| SUITBLE FOR |

| GASES |

AIR |

STEAM |

OIL |

WATER |

|

|

|

|

|

|

Salient Features

- Design Standard BS EN ISO 17292 (BS5351)

- Flanged Ends to ANSI B16.5 Class-150 (Drilled)

- Three Piece Design

- Superb in Quality and Performance

- Testing & Inspection Standard : 598

Technical Data

- Test Pressure (Hydrostatic):

- Shell: 31 Kg/cm²g(400 psig)

- Seat :21 Kg/cm²g (300 psig)

- Seat :10.55 Kg/cm²g (150 psig)

- Maximum Working Temperature: 220 °C

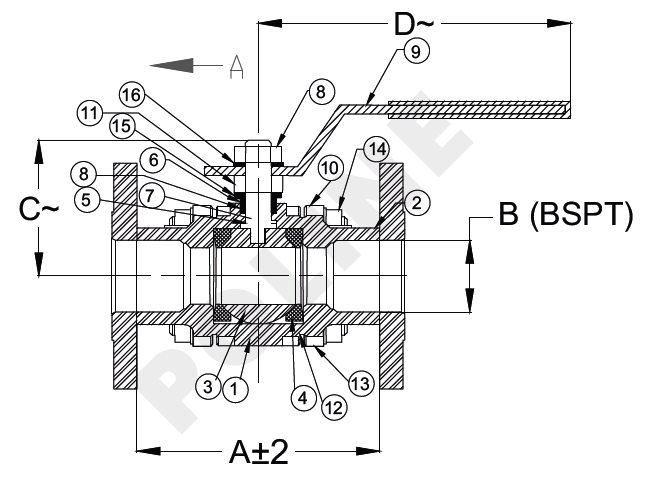

| MATERIAL LIST |

| P.NO |

Name Of Part |

Material of Constuction |

Specifications |

Qty. |

| 1 |

Body |

Cast Iron |

IS 210 FG 200 |

1 |

| 2 |

End Connector |

Cast Iron |

IS 6603 |

2 |

| 3 |

Ball |

Stainless Steel |

- |

1 |

| 4 |

Body Seat Ring |

PTFE |

IS 6633 |

2 |

| 5 |

Thrust Washer |

PTFE |

BS EN 12086-1 |

1 |

| 6 |

Gland Packing |

PTFE |

IS 1367 |

1 |

| 7 |

Stem |

Stainless Steel |

ASTM A 276 Type 304 |

1 |

| 8 |

Gland |

Carbon Steel |

IS 1363 |

1 |

| 9 |

Lever |

Carbon Steel |

IS 1367 |

1 |

| 10 |

Nuts |

Carbon Steel |

- |

8 |

| 11 |

Gland Nut |

Carbon Steel |

- |

2 |

| 12 |

Gasket |

PTFE |

EN 47 Gr.B |

2 |

| 13 |

Spring Washer |

Spring Steel |

ASTM A 193 Gr.B7 |

8 |

| 14 |

Studs |

Alloy Steel |

IS 1363 |

4 |

| 15 |

Cup Washer |

Stainless Steel |

IS 210 FG 200 |

2 |

| 16 |

Spring Washer |

Spring Steel |

EN 47 Gr.B |

1 |

|

SIZE / DIMENSIONS

|

| Size(mm) |

A+1.5 |

B |

OC |

OD+5.0 |

E(MAX.) |

The information provided here serves as guidelines only and is subject to possible modification.