| SUITBLE FOR |

| GASES |

AIR |

STEAM |

OIL |

WATER |

|

|

|

|

|

|

Salient Features

- Designed to meet BS EN ISO17292

- Features screwed female ends available in BSPT, NPT, or socket weld configurations

- Reduced bore with a three-piece construction

- Exceptional quality and performance

Technical Data

- Test Pressure (Hydrostatic):

- Shell: 20.7 MPa (3000 psig)

- Seat & Back Seat (Hydrostatic) : 7.6 MPa

- Maximum Working Temperature: 175°C

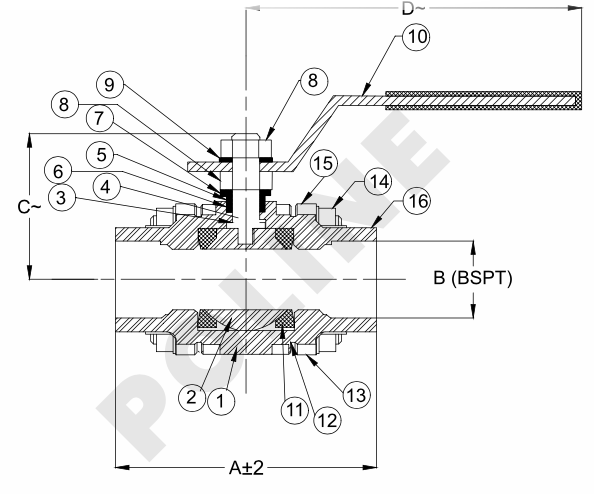

| MATERIAL LIST |

| P.NO |

Name Of Part |

Material of Constuction |

Specifications |

Qty. |

| 1 |

Body |

Forged Steel |

ASTM A105 |

1 |

| 2 |

Ball |

Stainless Steel |

ASTM A 276 Type 304 / ASTM A 351 Gr. CF8 |

1 |

| 3 |

Thrust Washer |

PTFE 35% Carbon Filled |

- |

1 |

| 4 |

Stem |

Stainless Steel |

AISI 304 |

1 |

| 5 |

Packing Ring |

PTFE 35% Carbon Filled |

- |

2 |

| 6 |

Gland |

Stainless Steel |

ASTM A 276 Type 304 |

1 |

| 7 |

Cup Washer |

Stainless Steel |

ASTM A 276 Type 304 |

2 |

| 8 |

Nut |

H.T Steel |

ASTM A 194 Gr. 2H |

2 |

| 9 |

Spring Washer |

Spring Steel |

EN 47 Gr. B |

1 |

| 10 |

Lever |

Carbon Steel |

- |

1 |

| 11 |

Body Seat Ring |

PTFE |

- |

2 |

| 12 |

Gasket |

PTFE |

- |

2 |

| 13 |

Spring Washer |

Spring Steel |

EN 47 Gr. B |

8 |

| 14 |

Studs |

Alloy Steel |

ASTM A 193 Gr. B7 |

4 |

| 15 |

Nuts |

H.T Steel |

ASTM A 194 Gr. 2H |

8 |

| 16 |

End Connector |

Forged Steel |

ASTM A105 |

2 |

|

SIZE / DIMENSIONS

|

| Size(mm) |

A+1.5 |

B |

OC |

OD+5.0 |

E(MAX.) |

The information provided here serves as guidelines only and is subject to possible modification.